The piping construction industry typically does not realise the importance of adhering to critical cleanliness practices during the constructing phase of process piping systems and pipelines.

Built clean, built on time, built with 100% inspection records.

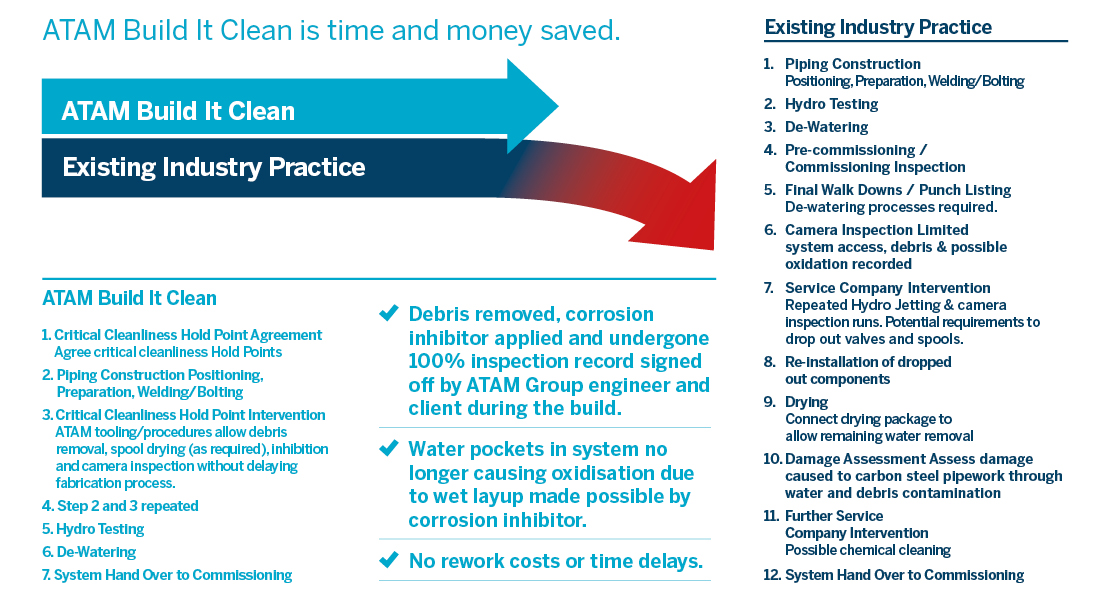

For decades within the Oil & Gas industry “Piping Cleanliness” has been viewed with less importance than it deserves. The result has been proven to balloon project budgets and, more importantly, delay both start-up and delivery times. The impact is felt on practically every piping construction project within the industry, with most experienced piping construction engineers having both experience of and exposure to problematic consequences due to corrosion or debris related complications.

ATAM Group have developed an innovative range of tooling featuring the ATAM Air Jet and software from the ATAM Asset Intelligence suite that can eliminate the necessity for the reworking of completed piping systems due to poor cleanliness management.

Our innovative tool is capable of cleaning, drying and inspecting in one rolex day date pour des hommes 36mm m118139 0060 bracelet en cuir regardez operation rather than three different procedures.

Preceding the construction of a process piping system, an ATAM engineer would suitably review the isometric drawings for that particular system. The engineer would proceed to identify “Hold Points” within that system and the drawing would be marked up accordingly with “Hold Points”. This would give clear identification of when one of ATAM groups cleaning and inspection devices would need to be introduced internally to the system. These “Hold points” would be spread throughout the system allowing full access to 100% of the pipework.

On completion of the build every inch of the piping system has been cleaned, dried, inhibited and inspected.

This means systems can be laid up clean and fully protected until hydrotest or pneumatic leak test operations have been completed.