Flange Management

Controlled flange management is a recognised technique for leak prevention in bolted flange assemblies.

Across a number of industries maintenance and pre-commissioning schedules are prioritising flange management from design in order to develop start-ups that are leak-free.

ATAM Asset Management facilitates the process of controlled tightening and its associated benefits, through the use of a specially commissioned software package, written procedures and bolt loading calculations, to ensure that joints are tightened in a safe manner.

ATAM Asset Management will capture the joint identification and information through the use of both 5 part barcoded flange tags and invincible barcoded stickers.

Controlled bolting and flange management are recognised components of a system’s integrity program. They provide assurance of proper assembly and tightening of bolted joints during the construction process, or any intervention that follows it.

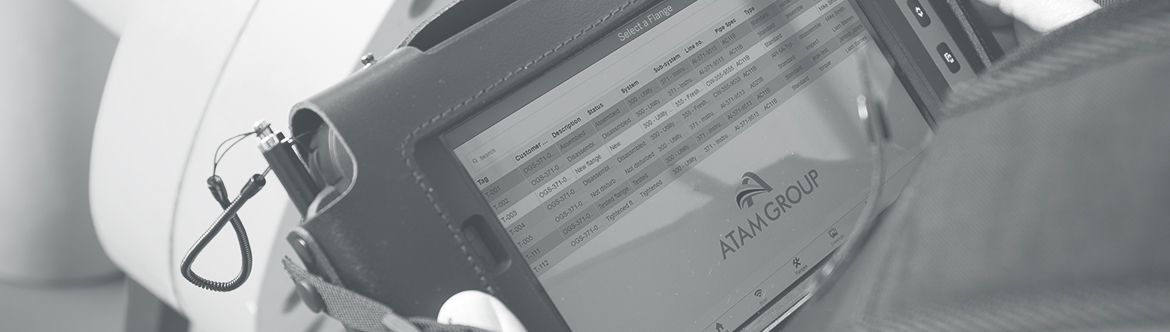

ATAM Groups software and revolutionary EX rated hand held units which include a 3D shot of the joint and spool in question, a camera for taking photographs of the completed joint to build up asset facilities management data, a built in GPS facility to guide the operator and locate the joint minimising the effect of https://mycopywatches.com/ downtime and increasing safety and are touch screen to allow for live sign off in the field for live feed reporting.

The Software package (ATAMS) is engaged with both of the ATAM Group divisions (Services and Asset Management)

Flange Management include:

Joint Data Management

P & ID, Isometric and 3D CAD

Barcoded 5 part Flange Tags and Barcoded Invincible Stickers

EX Rated Hand Held PDA for Field Identification and Live Sign Off

Safety feature allowing joint location and guidance to be shown on screen

Manual Bolt Torqueing

Hydraulic Bolt Torqueing

Hydraulic Bolt Tensioning

With ATAMS there is no hiding place only total transparency.